Christianson Systems, Inc. offers flexible solutions for a wide range of material handling applications. State-of-the-art technology backed by over 50 years of experience insure that each machine is built with superior quality, construction, and design.

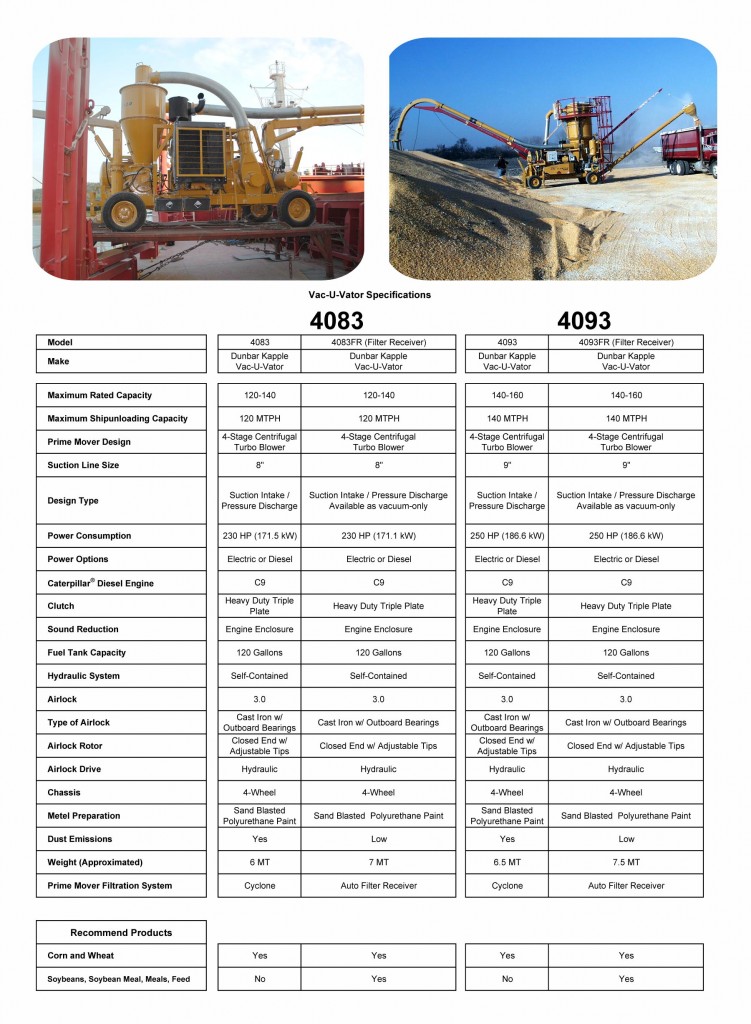

The DK Vac-U-Vator line of equipment is available in two models, the 4080, and 4090, providing ship and barge unloading solutions for a variety of pneumatic conveying applications. All models are offered with either a cyclonic cleaning intake cyclone or a filter receiver. The cyclone intake provides an efficient cyclonic cleaning with a back up screen to prevent carryover. The filter receiver (FR) is equipped with its own dry compressed air for cleaning the 10-micron filter tubes with a pulsed air system. When used as a vacuum only system this machine has low dust emissions. All models may be equipped with an intake and/or discharge boom.